Dust Collector

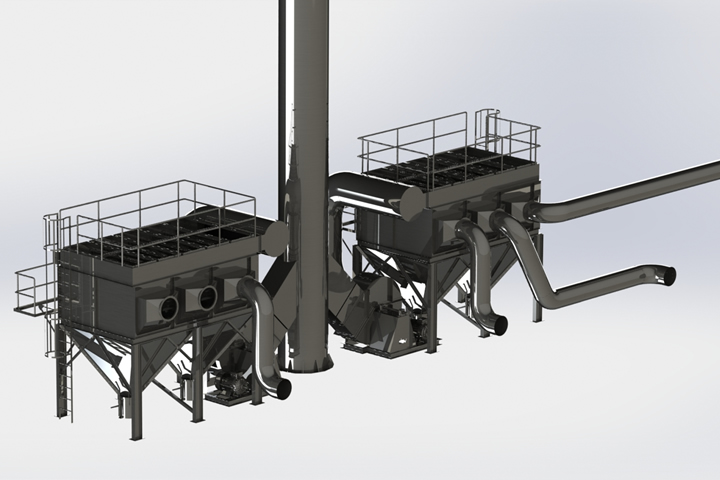

DAV makes all types of air pollution control equipment including filter bag dust collector, cartridge pleated filter dust collector, mechanical shaker dust collector, multi cyclones dust collector.

Each of our dust collector models come with following options / variation

- Offline and online cleaning filterbag dust collecting system.

- Filter media : polyester, homopolymer acrylic, PPS, Nomex, P84, fiberglass and PTFE.

- dust discharge via rotary airlock, screw conveyor, double damper valves, or lock-in bin.

Dust Collector Models

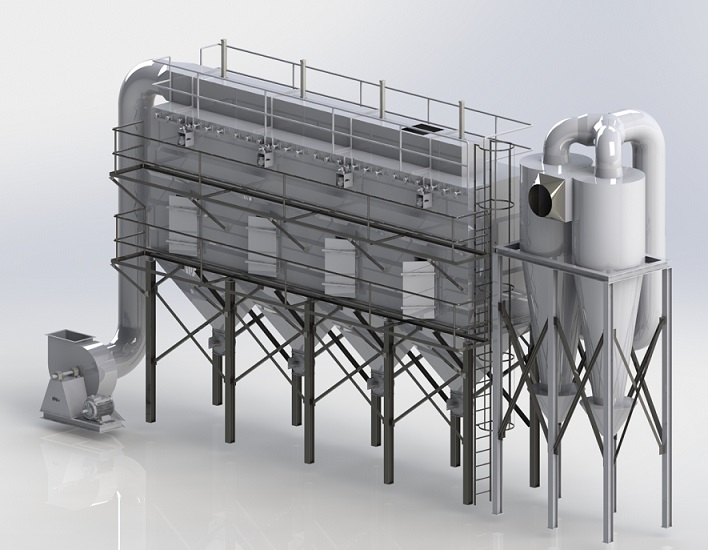

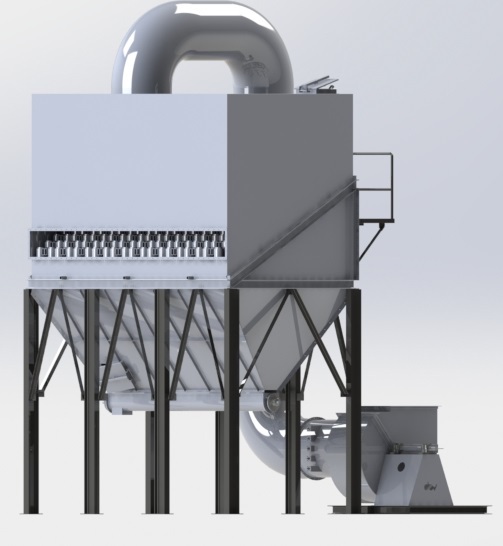

Pulse Jet Filter Cleaning Dust Collector

- Professional valve size and type selection

- Proper sizing of pressure header volume, compressed air consumption and nozzle diameter.

- Pressure header manufactured to ASME code Section VIII & IX for pressure vessel.

Mechanical Shaker Filterbag Dust Collector

- Motorised shaker eccentric shaft to produce oscillating movement to filter.

- Offline filter cleaning. Dust collector to have compartments for this purpose.

- Spark prevention feature.

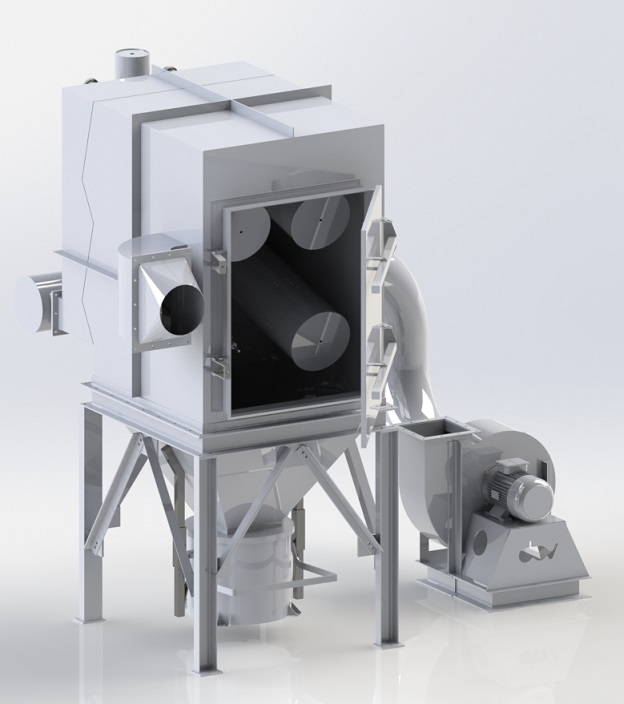

Cartridge (Pleated) Filter Dust Collector

- Cost competitive dust collector design

- Enhanced filter purging cleaning to counter dust plugging on filter.

- Suitable for low dust load application, non-sticky, non-fibrous, fluidized and dry dust

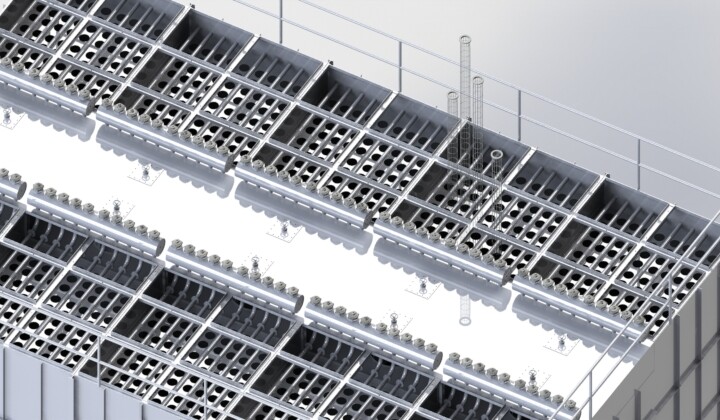

Multi Cyclone Dust Collector

Multi-cyclone dust collector is ideal for boiler ash dust collection. It is practical substitute for filter bag dust collector that can not withstand high temperature gas from boiler or burner. Multi-cyclone comprises numerous small-sized cast iron cyclone elements arranged in parallel and staggered. The small cyclone diameter ensures it is able to achieve ash-air separation efficiency as high as <75mg/Nm3 for coal-fired ash.

Cast iron cyclone elements packed for export shipment.